Does food-grade stainless steel actually exist? Or: myths that stainless steel and stainless steel products somehow rust.

We often see customers asking the same question: What kind of steel are your products made of? Is it really "food-grade stainless steel"? Or we hear that stainless steel is good, all others are not, etc. etc.

So we suggest taking a closer look at this question of whether the type of stainless steel—food-grade or otherwise—used in your products is actually important, and in which cases it will play a pivotal role in the final characteristics of your product.

There are three main grades of stainless steel available on the Ukrainian market: AISI 430, AISI 201, and AISI 304.

The first two grades are fairly similar in their chemical composition (the percentage of non-ferrous metal alloy) and their ability to be mechanically processed and welded.

The third grade of steel, AISI 304, is considered the most expensive due to the increased chromium and nickel content, which, theoretically, produces better "stainlessness".

But there's one "but", as they say. None of the above steel grades can be considered food-grade or not when compared to each other. Why? Because all surgical instruments, tableware, and appliances that you consider to be very high quality and safe are made from the cheapest on the list, AISI 430. Most people in Ukraine's HoReCa market find this grade to be neither food-grade nor magnetic, and it therefore cannot be considered more stainless than the other, more expensive steel grades.

When should I use 304 stainless steel?

Based on our almost 30 years of experience in manufacturing professional technological catering equipment, we can note that when the product (sink, work table, bar station, or other) will be used with aggressive cleaners or in a high-humidity environment like by pools or the sea (which also adds increased salinity), there is almost no alternative, if any, to AISI-304 if you want your equipment to maintain its appearance and features over the years. In all other cases, it makes sense to use other grades of stainless steel.

Why does your stainless steel rust?

1. During the production process, there are stages such as bending and welding in a protective argon environment that to higher or lower degrees affect the protective top layer of stainless steels, breaking it in places where it is bent or welded. Therefore, there may be slight rusting in these places even in a new product, but the protective layer on stainless steel is able to be restored by cleaning these areas with mild cleaners and non-aggressive methods.

2. The use of tap water without additional primary filtration may cause rusty deposits to appear on the surface of the stainless steel product. In this case, it is necessary to either purify the water further, which in most cases is not ideal, or to not pay any special attention to it.

3. In areas that are mechanically processed (through cleaning or grinding) like the corners of tables or washing machines etc., microparticles of the abrasive materials used for these procedures are quite often left behind. This means that when the finished product is being used, especially if the product is in contact with water (i.e., washing), slight rust-looking deposits will sometimes appear. These are the abrasive microparticles reacting with water and producing these deposits. This problem can be solved simply: just wash with a damp cloth and mild detergent first, and then wipe dry.

We won't add a fourth point about the constant care that any stainless steel product requires to maintain its appearance.

Thank you for reading to the end, and we hope you found this article helpful.

Worktop refrigerator, as an aggregate, with a price of usable refrigerated volume per 1 liter.

Frequently we don’t think about buying a worktop refrigerator in the kitchen, about its real “useful” volume and the price that we pay in the end for all this volume.

It would seem that such an important factor is practically not taken into account when the question arises of buying in your new project of catering establishments (restaurant, cafe, gastrobar etc) or already existing. Cause as a general price plays a decisive role for the owner of an institution.

Price of usable refrigerated volume of the refrigerator table per 1 liter. How to count?

jpg.jpg)

It is simple!

Let’s take for example and comparison the price of an average worktop counter fridge common and available for sale in Ukraine with dimensions of 1400x600x850 mm and volume of 205 liters, and Orest refrigerated counters RTD-2/6 1500x600x850 mm with 296 liters of its volume.

Refrigerated counters (price per 1 liter)

935,58 EUR / 205 L = 4,56 EUR

Orest RTD-2/6 (price per 1 liter)

1178,68 EUR / 296 L = 3,98 EUR

The difference from the example above is obvious. Usually in such tables, the volume is leveled by a dynamic cooling system, and the operator cannot arrange the overall product along the entire length in the space between the shelves of such table.

Such differences as a 2-year compressor unit warranty, a voluminous wallboard, hot items table top, possibility of ordering with wheels mounting (rollers), as well as both left-side and right-side compressor arrangement, make Orest worktop refrigerators a profitable purchase in all aspects.

Reviewof Orest commercial convection ovens.

Orest commercial convection ovens.

A logical step in the evolutionary development of the range of frying ovens was the development and creation of a model range of Orest commercial convection ovens of the EO (c) series.

They comply all modern requirements and trends in a professional kitchen, such as:

- long service life

- maintainability of the main components and assemblies

- work at the maximum temperature of a temperature mode in 300°C

- universality of use the accessories (gastronorms, baking sheets etc)

Long service life

In order for your convection oven lasts longer than one year in hard operating conditions – it has stainless steel construction (including internal components) with a thickness of 1-2 mm. At the same time, you can be sure that the design will retain its original appearance over the time and geometry. Everything that needs to be closed and opened will be. The main components and assemblies will not fail at the most inopportune time (peak load) - all critical components such as: the thermostat, rotary fan motor and fan are made in Germany.

Uniform baking at the maximum temperature of 300°C

The quality of the oven is determined by finished products that you can finally get, whether it be croissants, strudel or pork knuckle.

Responsible for this are the following components:

- stainless steel spiral heating element

- powerful thermal insulation of the chamber with basalt foil-insulated chamber 30 mm thick

- well thought-out design of the casing of the heating element (back wall of the oven)

|

|

All this in a complex will give an excellent culinary result.

Convenience in work (ergonomics)

Orest commercial convection ovens are equipped with all those attributes without which no modern professional oven can’t complete:

- camera backlight

- silicone heat-resistant oven door seal

- dial thermometer for visual monitoring of the temperature inside the oven

- universal removable guides for a baking sheet 600x400mm or gastronome containers GN-1/1

- ventilated door with double tempered glass (thereby eliminating possible burns to the operator)

- powerful, adjustable stainless steel legs will help you to level the installed oven horizontally

And such a constructive solution as a separate inclusion of each oven separately (for EO(c) -2 and EO(c) -3) - will allow you not to waste your resources in case your work does not require a full loading.

Hope you enjoy it. Sincerely your Orest.

New series - the third generation of industrial electric cookers Orest CES 700

Based on 25 years of experience in the development and production of professional electric ranges, we present the third generation series.

In the new series commercial electric cookers have:

-4-0(G).jpg) |

|

All this suggests that the purchase of a professional Orest electric range can be viewed as a profitable investment in the renewal of an existing technological equipment park of a catering enterprise, and at the opening of a new institution.

| CES-2 | CES-2(HD) | CES-4 | CES-4(HD) | CES-6 | CES-6(HD) | CES-4-OG | CES(c)-4-OG | CES-6-OG | CES-6-OG(HD) | CES(c)-6-OG | CES(c)-6-OG(HD) | |

| Quantity hobs | 2 | 2 | 4 | 4 | 6 | 6 | 4 | 4 | 6 | 6 | 6 | 6 |

| Presence of oven and type of heating | not available | not available | not available | not available | not available | not available | yes/static | yes/convection | yes/static | yes/static | yes/convection | yes/convection |

|

El. power of oven (kW) |

-- | -- | -- | -- | -- | -- | 4,5 | 3,0 | 4,5 | 4,5 | 3,0 | 3,0 |

| Open base cupboard | there's | there's | there's | there's | there's | there's | нет | нет | нет | нет | нет | нет |

| Doors of base cupboard | not available | there's | not available | there's | not available | not available | -- | -- | not available | there's | not available | there's |

About application of energy regulators in cabinet ovens. How does it work and why it is necessary.

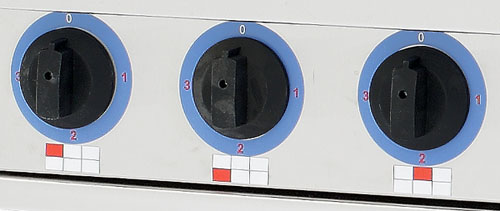

Many people are familiar with situation when the bottom or upper part of the product is slightly burnt during baking process in static heating oven, or the upper part is gratinated and the bottom part remains half-baked. The reason of all the listed problems is the fact that those static heating ovens have great temperature differential in the chamber. Sometimes it is impossible to solve the problem with the help of the temperature regulator, especially if the product height is quite big. As consequence of solution searching – specialists of Orest ^tm made a conclusion that it is necessary to reduce gradually the power of upper and lower heating elements. The most reliable and efficient devices for realization of the task are energy regulators of the German company E.G.O. Many manufacturers of thermal equipment in many countries of the world use these devices.

Devices mentioned above, are the simplest in operation and in understanding of application principles. The control knob of the regulator can be turned clockwise and counterclockwise. A click near “3” indicator means that heating is switched off, from “0” to “1” – is indefinite zone, where regulating is not occurred. Starting from “1” indicator – the power of heating elements is increasing from 10%, in zone of “2” indicator – the power is 50%, in zone of “3” indicator – 100%. In zone “1” - regulator turns on heating elements at 10% of total time range. If the control knob is turned clockwise, time of heating elements switching on is increasing, time of switching off is decreasing and in zone “3”, it achieves 100%. By turning of the control knob, we can gradually regulate the value of heat energy, emitted by heating elements and achieve necessary quality of the cooking product.

Guidelines for working with cabinet ovens and ovens with energy regulators.

Before starting, control knobs of energy regulators must be set in position “3” that corresponds to 100% of power, the temperature regulator must be set at temperature corresponding to temperature of product cooking. It is necessary to warm-up the chamber in the course of 30 minutes, when signals lamps die out – load the product into the oven and make an experimental baking. If the upper part of the product is baked more than necessary – it is necessary to reduce the power of upper heating elements. If the bottom part of the product is baked more than necessary - it is necessary to reduce the power of bottom heating elements. The amount of regulating is determined by the cooked product condition (the more difference between desired result and actual, the more amount of regulating). In such a way, the necessary result of cooking process is achieved.

Pizza ovens Orest, updating the range.

We’re present a significantly expanded and modernized line of professional pizza ovens from the Orest PO series.

What has changed, improved and what are the main "chips" and differences between the models?

-

As before - the design is only made of stainless steel with a thickness of 1-2 mm. Application in the design of steel with a thickness of less than 1 mm can lead to deformation of the oven camera at maximum temperature conditions, as well as burn-out of galvanized coating in case if this type of steel is using.

Corrosion is eliminated and surface cleaning is simplified - a stainless steel pizza oven is much easier to clean from even the heaviest soiling, including abrasive detergents. The most expensive and durable part of the oven is the hull, electrical appliances (switches, heating elements, thermostats) are not so expensive and will not make it a problem for the budget to replace them with new ones after some time.

-

Baking deck - all the same stone (ceramic) plates 15mm thick made of fireclay of the leading Italian manufacturer for many European brands - the choice of professionals, perfectly retain and distribute heat, are durable.

-

Thermostats (temperature regulators) produced by E. G. O. (Germany) do not demand in any recommendation. This is a guarantee of reliability and durability!

And now as regards the main differences.

There are not many differences, but they are. The older models PO-4 and PO-8 are equipped with a damper for steam (moisture) output and a handle for its control. Further, there are differences mainly in the temperature rates of 85 - 450 and 50 - 350, the dimensions and the capacity of the camera - by 1, 2, 4, 2 + 2 and 4 + 4 pizzas up to 32 cm in diameter, properly.

We have prepared some table for you, which clearly shows the main differences between the models.

| PO-1 | PO-2 | PO-2 450 | PO-2.2 | PO-2.2 450 | PO-4 | PO-4 350 | PO-8 | PO-8 350 | |

| Capacity per 1 camera (pizza up to 30-32 cm) | 1 | 2 | 2 | 2+2 | 2+2 | 4 | 4 | 4+4 | 4+4 |

|

Oven damper for removing steam from the camera |

- | - | - | - | - | + | + | + | + |

|

The maximum permissible temperature inside the camera 0C |

350 | 350 | 450 | 350 | 450 | 450 | 350 | 450 | 350 |

| Supply voltage (V) | 220 | 220 | 220 | 380 | 380 | 380 | 380 | 380 | 380 |

| El. power (kW) | 2.0 | 3.4 | 3.4 | 6.8 | 6.8 | 5.6 | 5.6 | 11.2 | 11.2 |

A window of heat-resistant glass 6 mm thick and halogen lighting of the camera are present in all Orest models. By the request of the customer the ovens can be equipped with a temperature indicator (thermometer, temperature sensor) on the control panel showing the current temperature inside the camera, depending on the set temperature.

Advantages and disadvantages of static and dynamic cooling in Orest refrigerated tables.

At the beginning let’s review a static cooling system because it was used in the most number of early models of household and industrial refrigerators; as it is seen from the title a static cooling system implies the absence of air circulation inside the refrigeration compartment (air immobility).

Notwithstanding in this case statics is a conditional notion, although air is moved very slowly, but it is moved: warm air inside the refrigeration compartment ascends up, while cold air descends to the lower wall of the refrigeration compartment (natural air convection is performed).

As a result of such air movement individual zones with temperature difference in 5-6 degrees Celsius occur in the refrigerated table that will enable to choose the necessary temperature zone for different types of products. In this case moisture is not evaporated, but remains inside the refrigeration compartment. When the compressor is switched off moisture is condensed on the back wall of the refrigerator and drips in the special evaporator. Just because of dripping such cooling system is often called as “drip cooling system”.

.jpg)

This system is operated on a principle of perpetual cycles: cooling – freezing – defrosting; refrigerated tables with static cooling system are equipped with hand heat controllers used for optimization of duration and frequency of these cycles. For defrosting purpose one shall switch it off and open doors. Defrosted and dripping to the tray water shall be poured out, the refrigeration compartment shall be wiped dry and ventilated. Recommended defrosting frequency of the refrigerated table is stated in technical specification of each certain model.

One should specify that the refrigerated table with static cooling is cheaper than the table with dynamic cooling due to easier construct.

One more significant advantage of refrigerated tables with static cooling is that there is no necessity to store products in a package because crusting effect of products is absent.

As for dynamic cooling, its main feature is actually absence of frost on walls of the refrigeration compartment.

Due to this feature dynamic cooling system is often called as “No Frost” (in translation from English it means “without frost”).

This result is achieved by means of air circulation inside the refrigerated table; the air circulation is enforced by special inbuilt fans. The evaporator is located behind the back wall of the refrigerated table; this evaporator ensures cooling of the back wall to the set temperature. With the help of fans a uniform distribution of required temperature inside the refrigeration compartment is performed; this excludes occurrence of different temperature zones and enables to ensure the best keeping of products. Temperature drops inside the refrigeration compartment can be maximum of 1-2°С that much differs dynamic cooling system from the static one.

Moisture that is removed by fans from the compartment of the refrigerated table settles in a form of frost directly on the evaporator without condensation, and as far as fans are switched alternatively with heaters frost is defrosting and evaporated quickly draining on purpose designed channels.

This feature of dynamic cooling system enables to avoid frequent manual defrosting of the refrigerated table. Most of the manufacturers of such equipment with dynamic cooling recommend to perform its defrosting only once or twice per year in preventive purposes.

It is important to note that unlike the static cooling that is used only in refrigerating systems, the dynamic cooling is equally used in freezing equipment too; such a flexibility gives one more advantage to the dynamic cooling systems.

In summary we realize that products are cooled better and faster in refrigerated tables with dynamic cooling system, because forced air cooling is available and refrigeration reaches the most hidden places in the refrigeration compartment of the table.

Shoud be noticed that refrigerated tables with dynamic cooling system are a little more expensive than with static cooling. Orest is the only domestic trademark in Ukraine that offers refrigerated table with dynamic cooling system.

Comparative testing of electric cookers Orest ПЭ 4 Ш (0,36) and ПЭ 4 Ш (0,36) 700 Eco. 35% energy savings.

We made one easy but at the same time useful experiment. We tested the electric cookers Orest ПЭ 4 Ш (0,36) and ПЭ 4 Ш (0,36) 700 Eco. The experiment lasted 2 hours, water was boiled in similar saucepans, in one place at the temperature 19° С. Initially the burners were cold.

During the experiment the water was boiled on 3 out of 4 burners and the 4th burner ran idle. So, the first electric cooker (cast iron burners) used 23kW, and the second electric cooker used less-only 15kW. As a result the difference is 8kW which equals to 35% of general energy consumption of the first electric cooker.

We’d like to consider if it is reasonable to buy cookers of “Eco” type from economic point of view. We took as an example the mentioned above electric cooker ПЭ 4 Ш (0,36) 700 Eco which took part in the experiment.

The cost of the electric cookers on the day of the test was the following:

1. - 6442 UAH.

2. - 12897 UAH.

As you may see, the difference was 6455 UAH.

There is a question: “Is it worth to overpay such an impressive amount of money for “almost analogous” electric cooker?”.

We can define if it is worth or not, making some simple calculations:

First of all, we calculated the average cost of electric energy for Kiev catering establishment - 1,23 UAH for 1 kW/ hour. The average working schedule of the establishment- from 10 a.m. till 10 p.m. daily (12 hour working day).

|

ПЭ 4 Ш (0,36) uses - 11,5 kW/hour. |

ПЭ 4 Ш (0,36) 700 Eco uses 7,5 kW/hour. |

|

Within one working day the electric cooker uses: 12х(11,5kW/hour х 1,23UAH.)=169,74 UAH. |

Within 1 working day the electric cooker uses: 12х(7,5kW/hour х 1,23UAH.)=110,70 UAH. |

|

Within 1 year: 360daysх169,74 UAH. = 61106,40 UAH. |

Within 1 year: 360days.х110,70 UAH. = 39852 UAH. |

So, the difference more than 20 000 UAH is in favour of the electric cooker of Eco type, with it you’ll cover the difference in the cost of the equipment in 4 months.

Operation of Orest electric cookers

Basic methods and Orest electric cooker operating principles which will help You save your time and money.

This article is recommended especially for owners of catering establishments which already have or plan to install Orest electric cookers. Actually when buying an electric cooker hardly anybody thinks how catering staff will use it. You can cut electric energy costs essentially and also avoid equipment downtime because of unpredictable damage if you follow some simple rules.

The rules are:

1. instruct staff, explain “postulates” of rules of work of electric cookers, and it does not matter if this cooker is with or without an oven.

2. When at least one burner is not used (there is no cookware on it)- turn the burner’s power switch in to the mode “1” (so called “Standby mode”- energy consumption will be considerably lower in this case), if there is a necessity to use this burner a little later during the day.

When you receive a new order i.e. you need to use the burner to prepare food just turn the switch into the needed mode and the burner will start working in a few minutes.

Since Orest electric cookers appeared on the market of professional kitchen equipment our service team has faced the same problem many times. The fact is that the catering establishments use the maximum mode of our electric cookers (large electric energy consumption, the cookers run idle without the cookware on the burner.

In this case the electric cooker works only to heat the burner and air around it, consequently the energy consumption is bigger and your expenses are increased.

3. Avoid penetration of liquids into the burners, as permanent penetration of large quantity of moisture causes breakdown which leads to equipment downtime. Instead of earning money You’ll need to spend your money and time on repair.

4. Do not put ware with cold water on the maximum preheated burner, because during sudden contact with cold objects the burner surface can be covered with cracks, and you’ll have to change the burners in a few weeks.

Prosperity to you and your business.

Sincerely, Oresttm

Specifications of stainless steel grades.

AISI 304 – Is the most highly alloyed steel as well it is the most universal and commonly used among all stainless steel grades. Its chemical composition, mechanical properties, weldability and corrosion / oxidation resistance are the most optimal for use in food industry. Equipment made of this steel grade proves its highest stability and reliability in severe operating conditions.

AISI 201 – This steel grade is relatively low-cost substitute of the AISI 304 steel grade due to partial substitution of nickel for manganese as one of the alloying elements. It is less durable steel than AISI 304.

AISI 430 – This is low-alloyed nickel-free stainless steel.

It is recommended to use as a substitute of AISI 304 steel grade.

It is suitable for operation in hot workshops. Equipment made of this steel grade is not recommended to be used in open air, where penetration of precipitation and enhanced radiation is possible. Penetration of corrosive acids, chlorine and other corrosives should be avoided.

откр.jpg)

.JPG)